SaiYin Joule Heating System

Show:0 Date:2023-11-20 08:00:33

In 1840, James Prescott Joule submitted a paper to the Royal Society detailing his experiments on the heat generated by electric currents in metallic conductors. He proposed that this effect was proportional to the conductors' resistance and the square of the current's intensity. More recently, Liangbing Hu, a professor at the University of Maryland, utilized rapid Joule heating technology to prepare a variety of new nanomaterials, including nano-particle of high entropy alloys, stable single atoms, and high-performance catalysts (Nature 2022, 605:470; Science 2018, 359:1489; and Nature Nanotechnology 2019, 14:851). In 2020, James M. Tour, a professor at Rice University, developed a method using high-voltage capacitors for flash Joule heating that can produce gram-scale graphene in just one second from various cheap carbon powders, such as carbon black, waste plastic and rubber, and numerous metastable phase materials (Nature 2020; 577:647).

Saiyin Materials Co., LTD. has developed a series of Saiyin Joule heating system that incorporates both flash and rapid Joule heating methods. To date, numerous research groups have used this system to uncover a range of intriguing results.

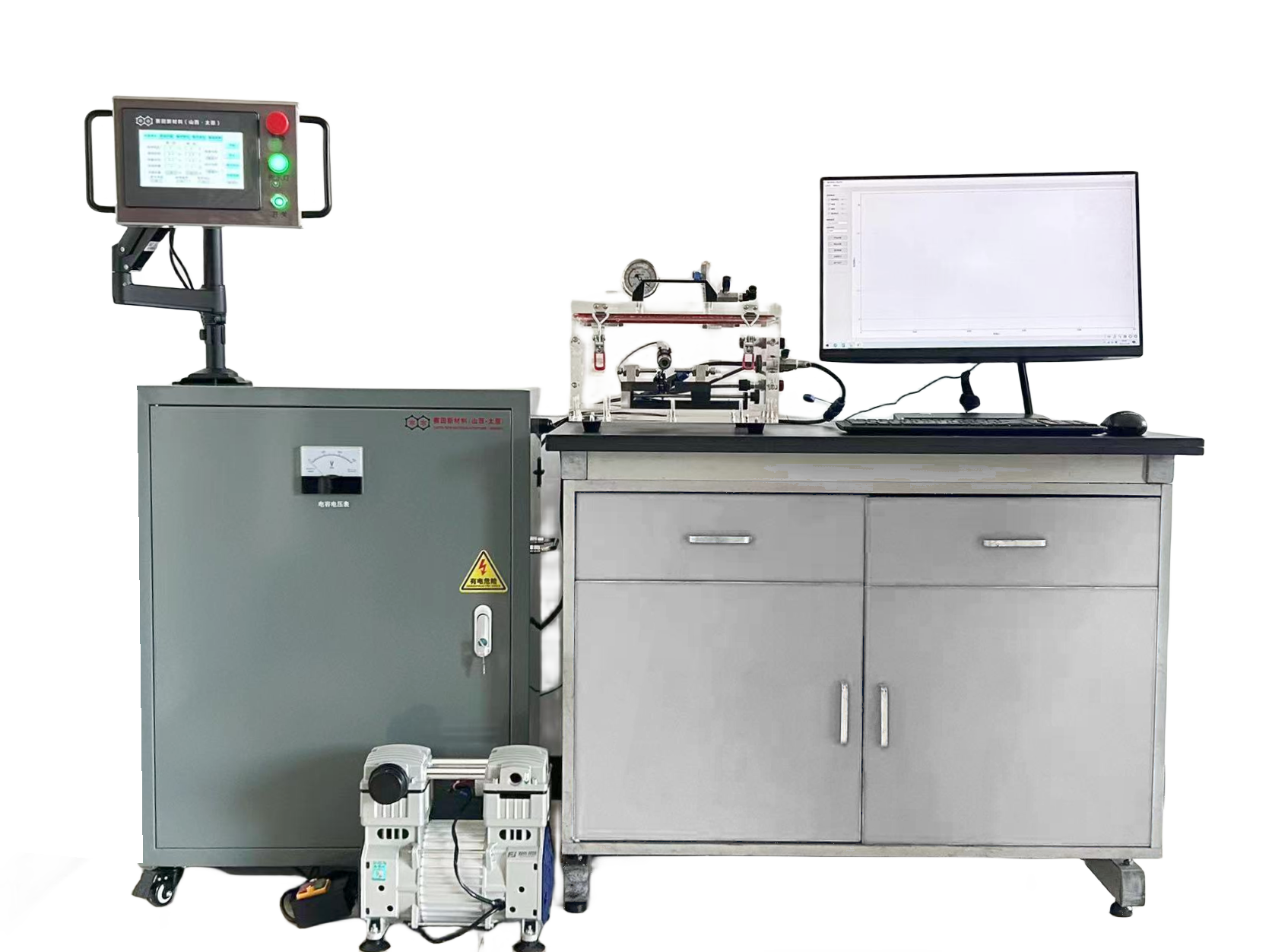

Fig. 1 Saiyin Joule Heating System (FJH-2024A Plus)

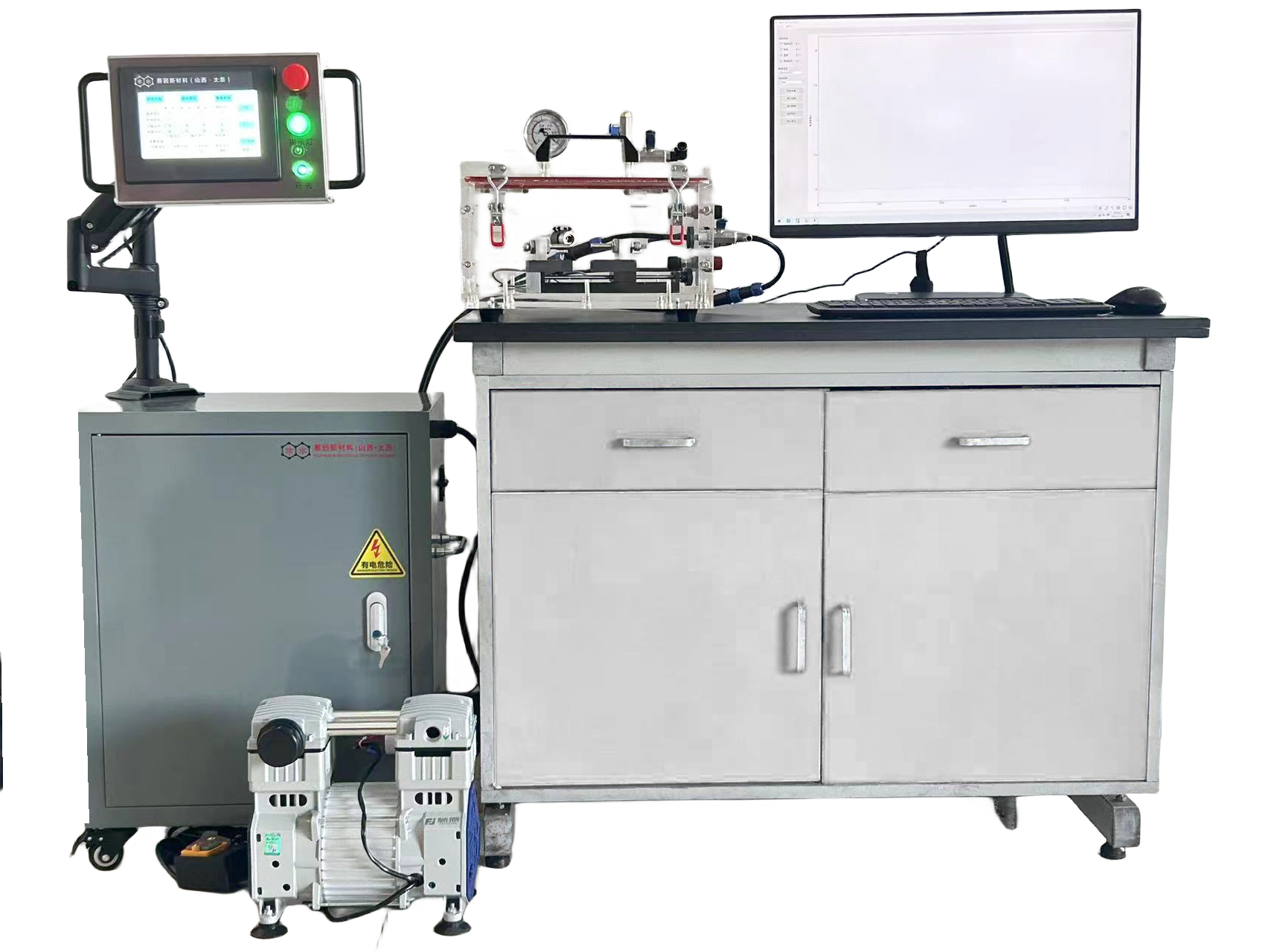

Fig. 2 Saiyin Joule Heating System (FJH-2024B)

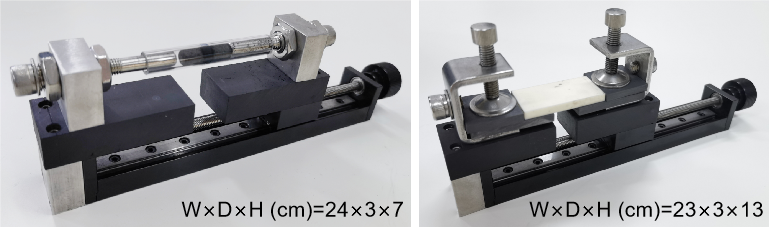

Fig. 3 Tube sample holder and slab sample holder

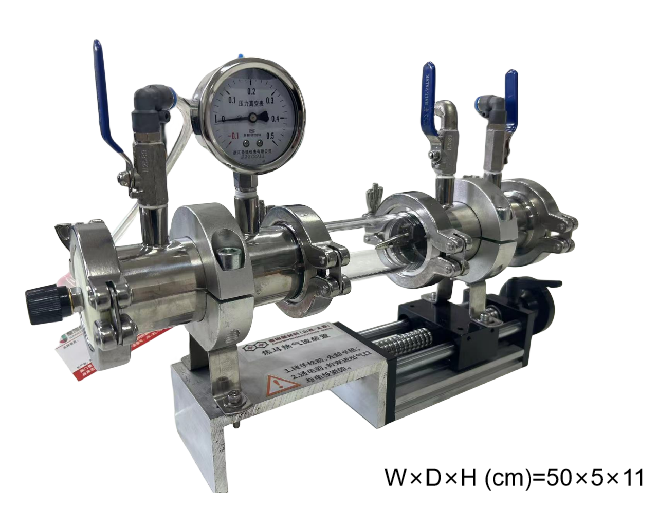

Fig. 4 Gas-flow reactor

Fig. 5 Gasification reactor

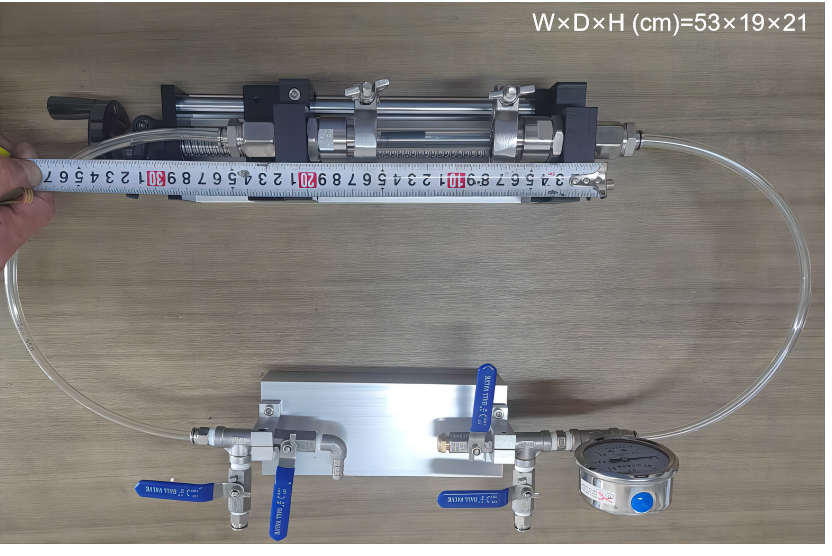

Fig. 6 Gas-solid reactor

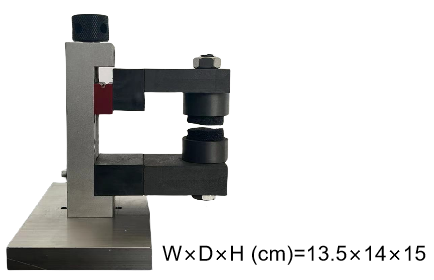

Fig. 7 Plasma reactor

Product specifications

| Product name | Saiyin Joule Heating System (FJH) | |||

| Model | FJH-2024A Plus | FJH-2024B | ||

| Equipment configuration | Power control cabinet, vacuum chamber,computer, vacuum pump | |||

| Power supply | Constant voltage, capacitor bank | Constant Voltage | ||

| Supply voltage | 110V/220 V | |||

| Total power supply | 3500 W | |||

| Constant voltage power | 3000 W (36 V×83 A) | |||

| Data acquisition | Real-time voltage, current, and temperature | |||

| Sampling rate | 1 ms | |||

| Capacitance capacity | 90±5 mF | - | ||

| Capacitor voltage | 0-300 V | - | ||

| Capacitor current | 0-600 A | - | ||

| Heating rate | ~10 5 ℃/s | ~10 3 ℃/s | ||

| Cooling rate | ~10 3 ℃/s | ~10 3 ℃/s | ||

| Temperature probe | Infrared temperature probe | Infrared temperature probe | ||

| Temperature range | 400-3600 ºC | 400-2800 ºC | ||

| Main Functions | Flash-, pulse-, step-, and flash-step heating | Pulse- and step heating | ||

| Cooling mode | Air-cooling | |||

| Vacuum chamber | Acrylic, square | |||

| Outer Chamber Size W×D×H (cm) | 40×40×30 | |||

| Inner Chamber Size W×D×H (cm) | 30×30×15 | |||

| Vacuum chamber volume | 13.5 L | |||

| Sample holder | Tube sample holder, slab sample holder | |||

| Heating source | Conductive sample, graphite felt, graphite paper, graphite paper in quartz tube | |||

| Sample test volume* | Powder: 0.5-2.0 ml (0.1-2.0 g); sheet: < 5×2×1cm | |||

| Overall weight | 110 kg | 60 kg | ||

| Optional reactor | ||||

| Name | Gas-flow reactor | Gasification reactor | Gas-solid reactor | Plasma reactor |

| Model | AF1.0 | FD2.0 | GS | PR |

| Size W×D×H (cm) | 50×5×11 | 36×17×63 | 53×19×21 | 13.5×14×15 |

| Main Functions | Depolymerizing for waste plastics and collect gases in product | Gasifying the components in reactant | Collect gases in product | Generate plasma from 3000 to 8000 K |

*When the sample testing volume exceeds 2 grams, a high-power power supply is required for testing.

Related ones:

- Saiyin 300 tons/year Joule graphene production line [2024-02-13]

- Gas-flow module for Joule heating [2023-11-23]

- Gasification module for Joule heating [2023-11-23]

- SaiYin Joule Heating System [2023-11-20]

- Slab holder for Joule heating [2023-03-12]

- Tube holder for Joule Heating [2023-03-12]